La 3D cell bioprinting It is a cutting-edge technology to create living tissues such as blood vessels, bones, cartilage or skin. Its progress has allowed since 2000 to intensify research on its applicability.

"Thanks to the ability to achieve spatio-temporal manipulation of various cells, bioprinting has become one of the systems that best recreates the cellular microenvironment of tissues, and with it, cellular behavior on a laboratory scale", he points out the specialist in studies with cellular models of Ainia, Dr. Lydia Thomas.

The application of 3D bioprinting has spread to different areas beyond regenerative medicine for tissue reconstruction. One of them is the pharmaceutical sector, to study the action mechanism of certain pathologies and identify new drugs, for example antitumor drugs or drugs to improve the cardiovascular system.

Dr. Lidia Tomás also points to the sector dermocosmetic, to create skin and study the effect of certain compounds or formulas. «Bioprinting applications are very beneficial for cosmetic companies, especially in Europe, where animal testing for cosmetics was banned in 2013. The main advantage that this technology offers is to test products ethically (that is, not on animals) on different skin types, for the most accurate results. In this sense, the L'Oréal group since 2016 has established a collaboration with the spin-off Poietis for the development of a 3D model of the hair follicle ».

Three-dimensional cell structures

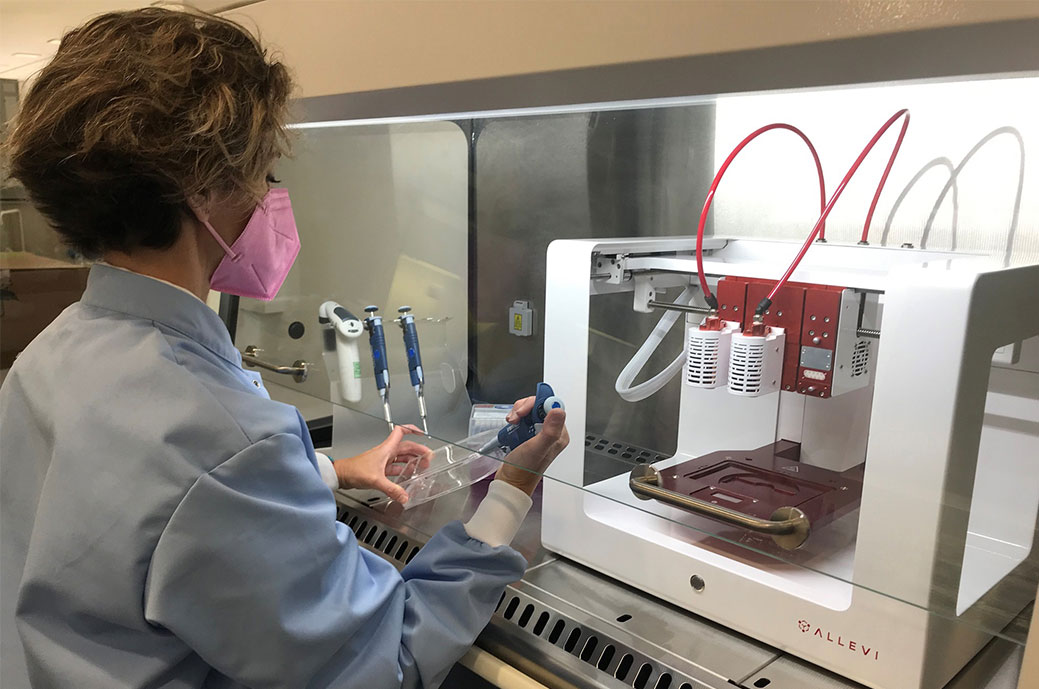

La 3D cell bioprinting is based on the additive manufacturing technology of 3D printing, generating three-dimensional cellular structures by adding a material layer by layer without the need for a mold.

The material that is added layer by layer is the so-called «biotin», a material that is loaded in the injectors of the bioprinter and that allows to mimic the architecture of the cellular tissue of interest. For the Ainia expert, the main components are: living cells representative of the tissue to be printed, either of one cell type or several; biomaterials for the generation of structures or scaffolds (the so-called scaffolds), among other collagen, gelatin or hydrogels based on hyaluronic acid or polyethylene glycol, components for cell maintenance, as well as other compounds or molecules that allow solidification or capacity of reticular (crosslinkers).

Given that it is difficult for a single material to meet all the properties to obtain the necessary characteristics, “one of the trends is to use multicomponent biotinks, so that the materials are usually combinations of several materials to achieve the desired mechanical properties as well as facilitate the printing capacity ", says Lidia Tomás.