"Spain is very important to us"

In 2017, as a result of the merger of the Reno De Medici Group, Cascades La Rochette and Careo Group, RDM Group was born. At the end of the following year, it buys 100% of RDM Barcelona Cartonboard, which has recently signed the preliminary agreement to acquire La Papelera del Principado SA (Paprinsa). RDM Group is the second European producer of coated cardboard made from recycled fiber, the first in Italy, France and the Iberian Peninsula. It is listed on the Star segment of the Italian Stock Exchange SpA and the Madrid Stock Exchange and its turnover amounts to 702 million euros.

In how many countries are they present? What does Spain represent for the Group?

The headquarters are in Milan but it has a strategic presence at the international level thanks to its 7 manufacturing plants - 3 in Italy, 2 in France, 1 in Germany and 1 in Spain -, 2 cutting centers and an active commercial network in 70 countries.

The Barcelona-based factory is RDM Barcelona Cartonboard, which produces recycled cardboard (WLC) and if necessary also virgin cardboard (FBB), at the service of the packaging industry in Spain and abroad. The acquisition is effective as of October 31, 2018.

But Spain is very important to us for another point: on September 30 RDM Group announced that its subsidiary RDM Barcelona Cartonboard SAU has signed four preliminary agreements for the acquisition of 100% of the capital stock of four companies incorporated in Spain. The agreement includes the acquisition of one of the main European players in the coated cardboard industry, Papelera del Principado SA (Paprinsa), and three smaller companies that operate in contiguous businesses based in the same area: Fergerdell SL, Cogeneració del Pla SA and Ondupacart SA.

What does Paprinsa specialize in?

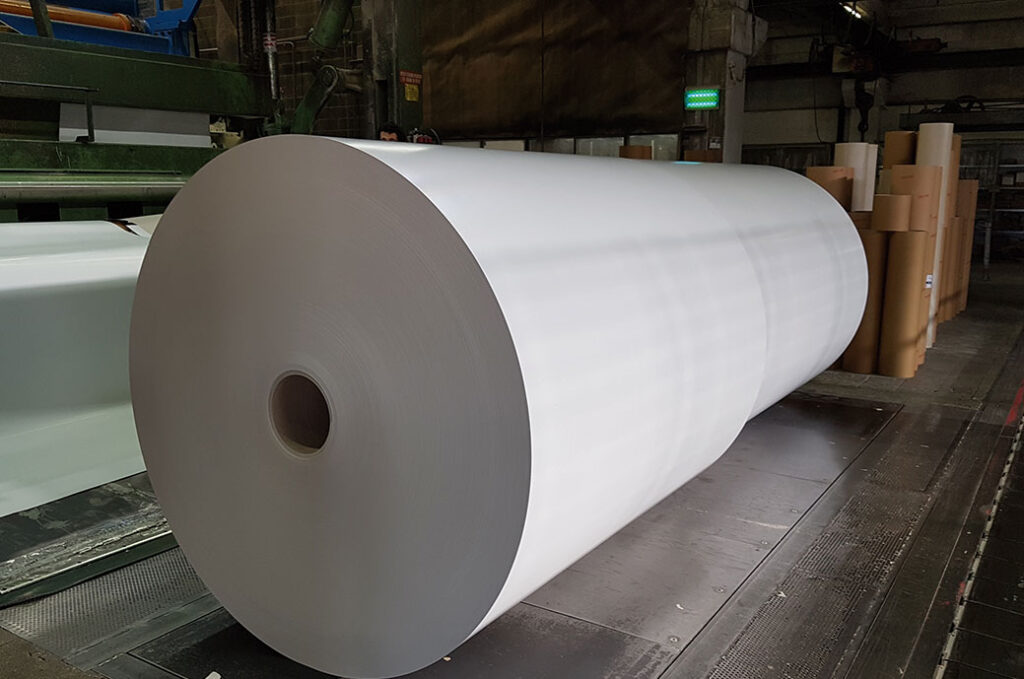

Founded in 1977, Paprinsa operates in the recycled cardboard business (WLC). The company has both its headquarters and the factory in Mollerussa, just 130 km from Barcelona and less than an hour from RDM Barcelona Cartonboard plant. It manufactures 120.000 tons of recycled cardboard, with a potential capacity of 140.000 tons. In the last six years, Paprinsa has made significant investments of more than 30 million euros in its plant. The production includes a wide range of grades and weights (from 180 to 550 g).

Currently, Paprinsa is the second largest producer of recycled cardboard in Spain and the eighth producer of WLC in Europe. The paper mill has a cutting width of 4,8 meters, which will make it the RDM Group's widest plant, as it is one of the largest paper mills in this sector in Europe. By further exploiting this size, RDM Group can count on a potential increase in the factory's production capacity from the current 140.000 tons per year to more than 200.000 tons per year, in line with the other major plants that are now part of the Group.

And the other three companies?

Ondupacart SA is a small manufacturer of corrugated cardboard.

Fergerdell SL is the real estate company that owns the 30.000 square meters in which the two manufacturing companies are located.

Cogeneració del Pla SA is the old cogeneration plant recently sold to Paprinsa. Currently, the company provides maintenance services to both plants.

At the end of 2018, the RDM Group bought Barcelona Cartonboard. What has this acquisition brought you and what synergies have been established?

The acquisition of Barcelona Cartonboard helped us to strengthen our leadership position through two pillars: maximizing the profitability of BC integrated in RDM Group and extracting synergies. The first is possible thanks to the optimization of the means, sharing the know-how of the companies, maximizing the strategic investments executed in 2016 and 2017 and reviewing the investment plan for the coming years, aiming for a double-digit EBITDA margin at from 2021.

The synergies, which will be fully achieved from 2021, are produced by the optimization of the product portfolio, the concept of multiple factories, the reallocation of the customer base and benefit from an improved economy of scale.

What is RDM Group's "vision" as a Partner of Choice?

Our Vision is to be a Partner of Choice through 3 strategic objectives: to offer excellent products and services, optimize costs and maximize the satisfaction of our key stakeholders. To implement this, we have worked around a One Company approach, drawing synergies through an integrated business model that sees the multi-factories company as one. Today, many functions have been centralized with a strong local connection to maximize specific needs versus group results.

How is the current situation affecting the company due to the pandemic?

As someone said, we believe that victory comes from finding opportunities in trouble. In reality, the pandemic has favored us in some way and that is for two reasons: RDM Group is inserted in the so-called essential supply chain, and that is the reason why we have never had to stop the factory. The second reason is that the blockade has increased domestic consumption, generally on food, and this is our main business. In general, we have reacted quickly to minimize the risks related to the pandemic through disinfection, strategically placing hand sanitizer, temperature scanning of employees, quarantine for employees who have traveled, increasing the frequency of intervention of the cleaning team, equipment personal protection, social distancing, smart work, daily follow-up call, Covid-19 Risk employee insurance. Just to mention the main measures taken.

RDM offers a broad product portfolio consisting mainly of recycled cardboard (GD / GT) and virgin fiber cardboard (GC).

What are your star references?

Our main business is the production of recycled cardboard and it can be the standard GD / GT, but also the Liner business. This is where we can take advantage of the multi-factories concept we referred to earlier and where flexibility in terms of business management expresses the best value.

Are you planning to introduce new products?

We continually seek innovation and development, although the industry has limited opportunities for pure new products. Currently there is a huge amount of possibilities to extend the application of fiber-based products to replace other materials, such as plastic, something that we are more than willing to accept as a challenge. Not forgetting the sustainability of our products, made with natural fibers and recycled more times instead of wasting them as rejected packaging.

What sectors do they work for?

It depends on the cardboard. Recycled cardboard (GD) is required for food, sports, toys, detergents and beverages; Liner for hardware, software, display, microflute laminate; Specialties (GT) for textiles, footwear and paper articles; Virgin Board for pharmaceuticals, beauty and health care, food, retail and bakery.

What measures are you implementing to achieve more sustainable production?

The sustainability pressure on packaging has increased significantly in the last 24 months. At the same time we can take advantage of interesting market opportunities: Circular Economy, Plastics Substitution and E-commerce / Multichannel Purchases.

For this reason, we are building partnerships with strategic end customers, converters, and European R&D institutes for specific product development purposes. We are also strengthening our partnerships with universities, primarily for talent recruitment and input of ideas.

RDM is part of several associations linked to the development of the packaging industry.

Just to give a few examples: RDM Group is committed to 4Evergreen, an alliance to promote paper packaging solutions in the direction of plastic replacement. It is home to more than 50 different companies that comprise the total supply chain for paper packaging, from the collection of recycled paper and raw materials through the production and conversion of pulp and paper / cardboard, as well as brand owners and retailers. Another association of which we are part is EPPA (European Paper Packaging Alliance), which represents suppliers and manufacturers of renewable and sustainable cardboard and cardboard packaging for the food and food service industry. It is an approach of concessions and mutual benefits within the scope of being associated with the industry.

What are your short and medium term goals?

Continue to improve the Group's operations as has been done in recent years. We still have many ideas and plans to implement, including the digitization of the company. Not forgetting the integration of the latest acquisitions and continuing to seek profitable expansion.