The personal care and beauty sector - Beauty and Personal Care - demands annually, according to 2019 data, more than 151 billion packaging units, positioning itself as a key industry for the entire packaging value chain, only surpassed by the food and beverages sector. On December 9, the Beauty Clusterand Packaging Cluster They shared cross-cutting knowledge about the trends in cosmetic packaging that we will see in 2021.

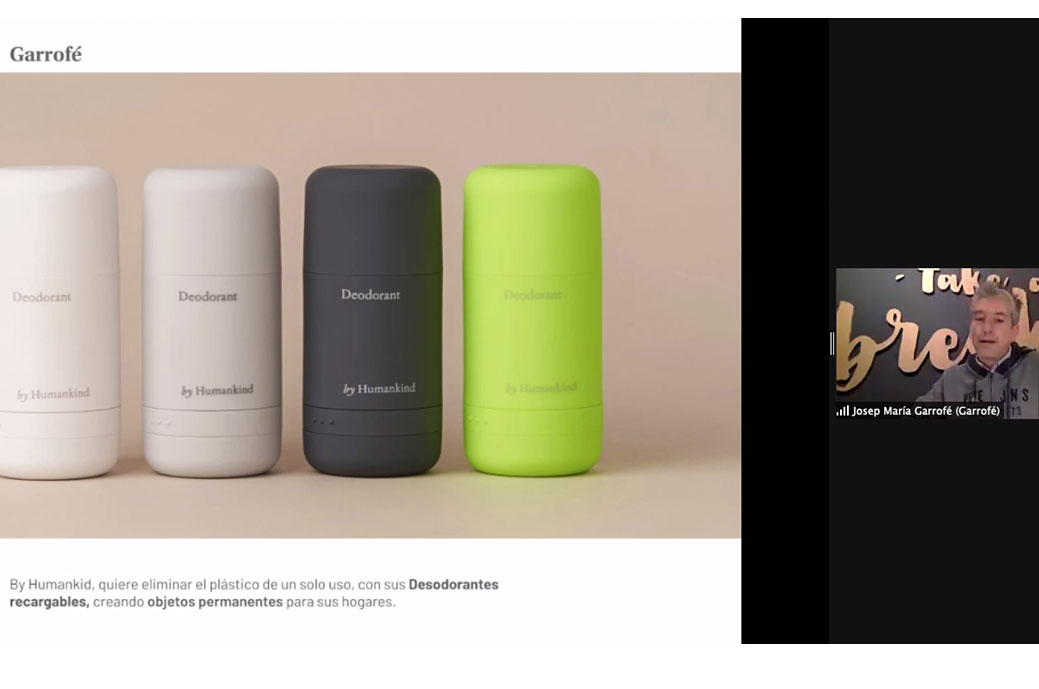

The online event began with a presentation by Josep Maria Garrofe, Design & Packaging Atelier de Garrofe, which highlighted four trends for the coming years: sustainable packaging, which "more than a trend, is an urgency"; minimalist packaging, "the new luxury is simplicity"; online, with designs adapted to the cartoon format, the unboxing that leads to a new secondary packaging and influencer packs; and smart packaging, "an increasingly important trend for marketing that will contribute to consumer loyalty", as it uses artificial intelligence to connect with the customer, an example of which is personalized cosmetics powered by artificial intelligence.

In a second block, both clusters presented during the day a brief report on the current cosmetic packaging market and the prospective 5 years ahead, with data extracted from the world database Euromonitor. As explained Serena Rebollo, Communication and Marketing of the Packaging Cluster, «in Spain, the subsector that consumes the most packaging is Hair Care -hair care-; rigid plastic is the preferred material for cosmetic packaging, both in Spain and in part of Europe; and Germany is positioned as a potential market niche in which to invest ”.

He also explained that color cosmetics have been the Beauty and Personal Care subsegment least affected by the pandemic, while fragrances have been the most affected; the global beauty industry expects to incur losses in 2020. Other consequences have been the expansion of metal aerosol cans to other categories, encapsulated products to preserve content, and the innovation and growth of single-dose containers, especially in skin care.

Round table

This was followed by a round table, moderated by Maica Garcia, director of News Packaging, with representatives of leading companies in the sector: Anna Scribe, CEO of Rafesa; Denia Martinez, Vice President of the Carinsa Group; Joaquim Llorente, Group Chief Innovation Officer of Zobele Group; Maite Fernandez Orue, General Director of Tapser SA; Tim eaves, CEO & Founder of Quadpack; Y Vicenç Pedret ClementeCEO Ramon Clement.

During the meeting, the issue of sustainability was perceived as an axis that affects the entire business strategy of the organizations present. Anna Scribe He stated that "we must find a balance so that the materials used in the manufacture of packaging are respectful, worked and developed, going through the whole process to be more efficient". For its part, the Carinsa Group also works in this area, as stated Denia Martinez: “In line with trends, we began to study the encapsulation of fragrances and aromas. It is a new technology and process that the Carinsa Group is developing that allows the reduction of microplastics that end up in the sea, a very important environmental impact ”.

Likewise, Joaquin Llorente placeholder image He explained part of the strategy used by the Zobele Group and that is that: “as an innovation center, we work hard on customizing the product, along different axes, both when the consumer goes to buy, and when they open and experience it, as well as repeat moment, which is when you buy a product from our range again ”. In Tapser, Maite Fernandez He highlighted the importance of adapting to what the customer wants, “we pay close attention to the end consumer. There is a gap between the manufacturing companies and this final consumer and from Tapser we work to reduce this distance ”.

To finish, Tim eaves He assured that “to achieve a positive impact, three holistic axes must be worked on: the product, the process and the people. In the processes, for example, we use renewable energy, bioenergy with the remains of wood from the plugs, and we have supported communities since the founding of Quadpack with education projects on how to recycle and protect the environment ”. Vicenc Pedret concludes with the social responsibility of Ramon Clemente, which "at the level of innovation, we are fighting for the recycled glass to be PCR (Post Consumer Recycled) in the highest possible percentage, which is not far from being compatible with product customization" .