La Artificial Intelligence (AI) It has become one of the technological phenomena of the moment. The unprecedented advance of computer processing in recent years has allowed the development of hardware that allows handling large amounts of information and the data necessary to make AI a reality in multiple sectors. This is leading the industrial sector to also opt for the introduction of AI in its automation processes. This is confirmed Universal robots, a world leader in the manufacturing of collaborative robots, which in recent years has introduced automation solutions that combine collaborative robotics and Artificial Intelligence.

The knowledge of the Danish company in the implementation of robotization processes has allowed it to identify four substantial improvements in industrial automation thanks to AI: human perception, adaptation to change without reprogramming, precision in moving parts and improvement keep going.

Human perception: human-like perception thanks to AI

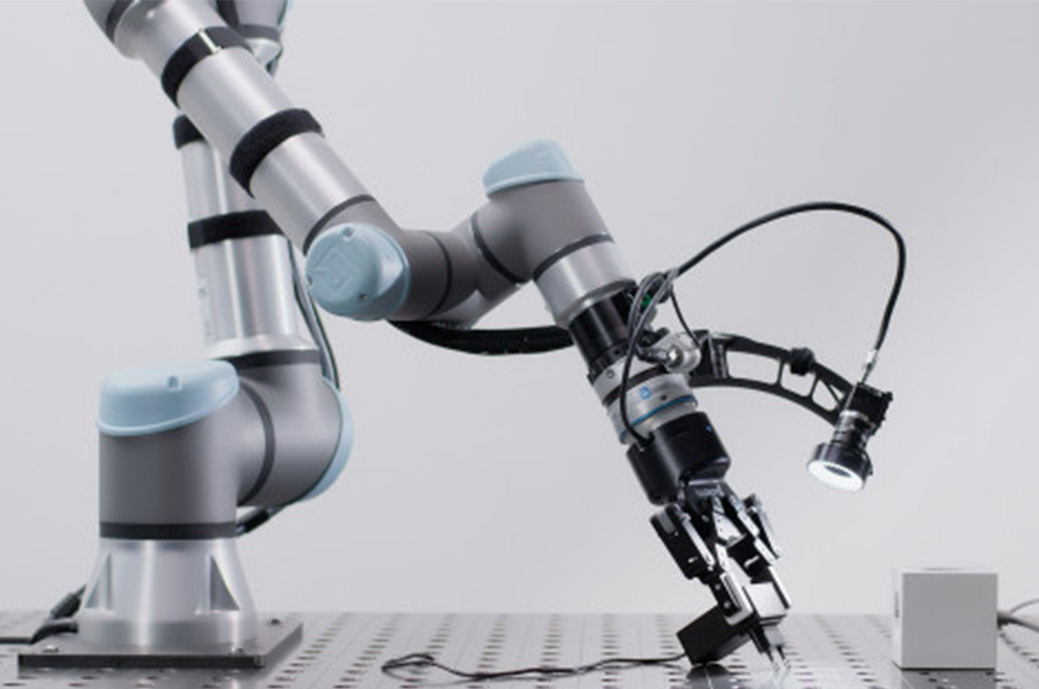

Chaotic item picking with robots was considered one of the most difficult problems to solve in an industrial plant. But that has changed with Artificial Intelligence. An example of this is Apera AI's 4D Vision technology, which challenges the status quo by providing collaborative robots with human-like perception. This solution allows faster and more effective robot operation, especially in applications of bin picking.

“Through the use of scanners and cameras, 4D Vision selects the easiest objects to pick up and tells the cobot the fastest and safest way to manipulate them,” he explains. Anders Billesø Beck, Vice President of Strategy and Innovation at Universal Robots. The solution can estimate the orientation of an object and obtain data to ensure the robot takes a safe, collision-free path to achieve its goal.

Adaptation to change without reprogramming

Most automation solutions in factories are programmed to handle an object with defined dimensions. However, the introduction of AI allows technology to think for itself and make decisions without prior instructions. The Robominds robobrain.vision kit, designed to carry out tasks such as kitting, order preparation or depalletizing in the logistics sector, allows us to overcome this barrier that industrial automation had until now.

The Robominds solution, equipped with cameras, makes it easier for the robot to pick up objects of different shapes and sizes. By not having to spend time training or programming the robot, users benefit from even greater flexibility, allowing them to add new objects to work with without wasting time reprogramming.

Precision in moving parts

Another example of how AI allows industrial robots to cope with any change in position, shape or movement is MIRAI, from Micropsi Industries. Instead of relying on specific pre-programmed measurements, the solution can generate robot movements in real time. Thanks to this, the cobot can carry out assembly, clamping, screwdriving or quality control tasks, even if the position of the machines or parts fluctuates from time to time.

Inbrain, Inbolt AI solution, is another technology that uses Artificial Intelligence to handle variations and moving parts. It processes massive amounts of 3D data at high frequency and identifies the position and orientation of parts, adapting the robot's trajectory in real time, a characteristic that makes it optimal for assembly, gripping, finishing and inspection.

Continuous improvement: collecting data to optimize automation performance

Another notable advantage of AI in industrial automation is that it improves constantly and automatically. The harder the robot works, the more data the Artificial Intelligence application collects. Using this data, its algorithm can continually optimize, tune, and improve the cobot's performance. This self-learning capability allows automation processes to be continually optimized.

“The synergy between AI and collaborative robotics solves extremely complex tasks, even in unstructured environments,” summarizes the Vice President of Strategy and Innovation at Universal Robots. “At the same time, the combination of cobots and AI provides manufacturers with a high degree of flexibility and simplicity while increasing the quality and reliability of processes,” he adds.