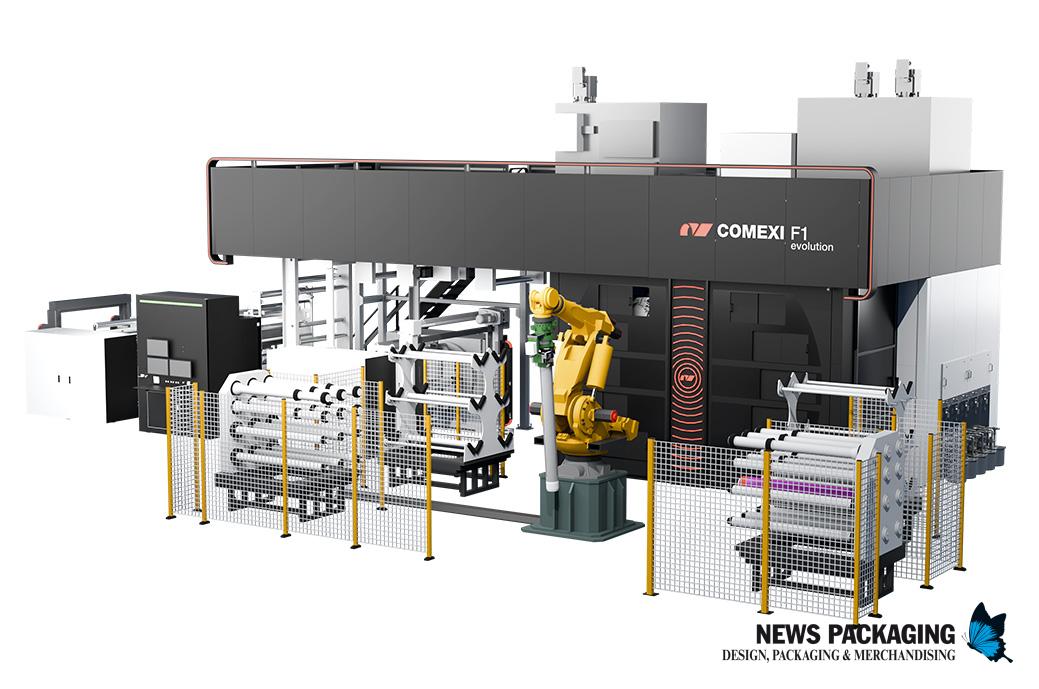

comexi presents two new models at Drupa 2024. Within its range of flexographic printers, and after the new F2 Evolution and F2 Origin, and together with the renowned F4, it presents for the first time the new F1 Evolution. This machine has been designed to be the benchmark for the highest-end flexo printers in the sector. Its printing speed of 600m/min and its printing width of up to 1690 mm with developments of up to 1260 mm stand out.

La new F1 Evolution It can be equipped with a robotic arm for changing liners and anilox, as well as the rest of the automations of the GeniusTech range developed by Comexi, such as Genius Print for initial SetUp with a single touch, Genius Dry for adaptable drying and efficient in energy consumption, Genius Flow for automatic and fast cleaning, or its ergonomic design that facilitates maintenance and cleaning.

Carles Rodríguez, Director of Printing at Comexi, comments regarding this solution: “the new F1 Evolution is an unparalleled piece of engineering that culminates the renewal of Comexi's portfolio of central drum flexographic printers. This new range represents a true revolution for the sector. It is a printer with a multitude of innovations focused on responding to the challenges our customers face. A good example is the Genius Board that automatically calculates the most efficient way to perform a job change, guiding operators step by step, or the new Genius Run HD system, thanks to which bouncing and sweeping are a thing of the past, Results are spectacular, reaching 600 m/min in the most demanding jobs. “We are proud to be able to present it at drupa 2024. At the end of the year it will also be available at our Technology Center in Girona to carry out tests with our customers and share the incredible F1 Evolution experience.”

At Drupa, Comexi will take a step forward in its commitment to Offset technology. This technology offers high printing quality, fast time to market and significant savings in prepress costs. However, its greatest advantage lies in its sustainability, highlighting the ability to print with Electron Beam inks and varnishes that reduce the amount of solvents, CO2 and VOCs, in addition to making the packaging more recyclable through the use of monomaterials. These innovations not only improve the sustainability of packaging, but also promote a cleaner and healthier environment by reducing the emission of atmospheric pollutants.

The novelty presented at Drupa 2024 regarding Offset is the expansion of the range to new developments. The Offset CI continues to grow with a new, wider model, with a 1320mm material pitch (1270mm printing width), to respond to the flexible packaging and paper markets. And to gain automation and printing quality, it also launches its Color Closed Loop system that allows controlling color stability during the print run without the need for printing marks, through a viewing system with 100% inspection.