The vaccine against coronavirus and other vaccines They are usually stored and transported in extremely cold conditions, which can be as low as -70 degrees Celsius, before being thawed and ready for administration. The secondary cardboard packaging it must be able to withstand these extreme temperatures and protect the vials throughout the process.

When a transformer produces packaging for cold chain transport, it has to be 100% sure that the materials it uses are the right ones. Metsä Board respond to this need with its test and simulation in deep.

"The cardboard for pharmaceutical packaging It must retain its predetermined thickness, its mechanical strength and its water absorption properties, regardless of the conditions it is faced with, and it must not affect the primary packaging in any way. Any change in dimensions could cause curling or bulging, which could pose a risk to the integrity of the container and, therefore, to the safety of the product it contains. We can test carton and packaging samples in both extreme cold and extreme humidity conditions, and develop packaging strength simulations to demonstrate how a package will perform in the real world, "he says. Markku Leskela, Vice President of Research and Product Development at Metsä Board.

In his Äänekoski Center of Excellence, in the center of Finland, Metsä Board has the ability to test the performance of carton samples and pharmaceutical packaging in a wide range of temperature and humidity. Conditions can vary depending on the specific needs of each case, and different cyclical changes in temperature and humidity can also be programmed to mimic the real conditions that vaccines face as they travel through the supply chain.

“With the help of a local partner we can test packaging samples down to -70 degrees Celsius and combine transport tests with carton conditioning tests,” says Leskelä. “This kind of in-depth research gives our customers the assurance that the cardboard they want to use is appropriate for the application in question. And if the results show that it is not, we can recommend an alternative.

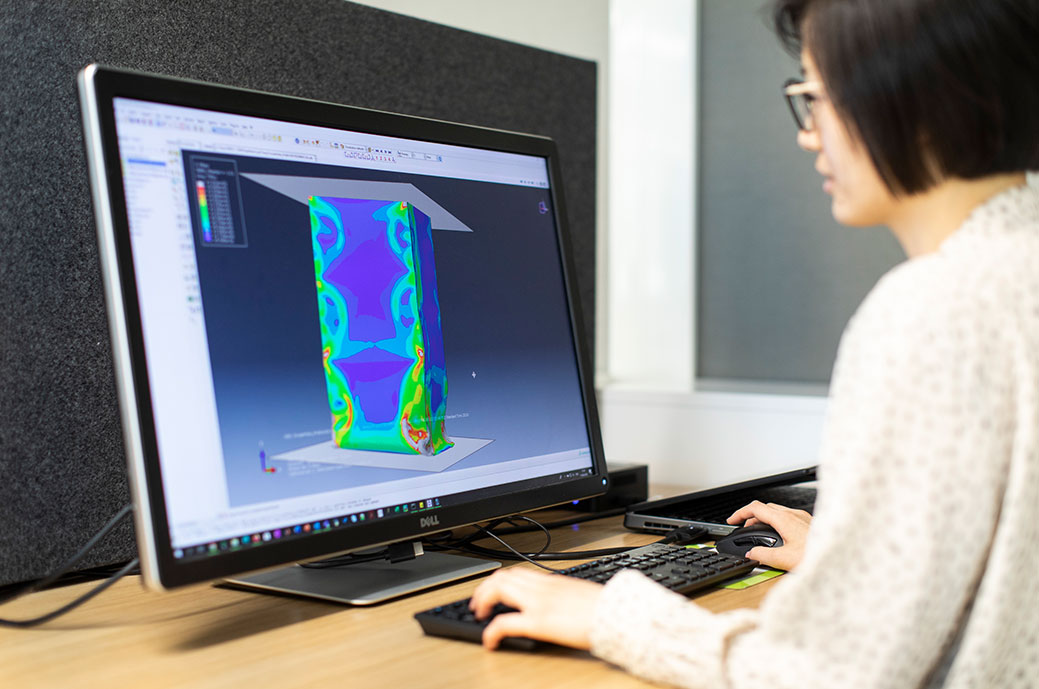

Metsä Board's simulation capabilities include Finite Element Simulation (FEM), where it is possible to take a 3D design drawing or measure the dimensions of an existing container sample, and use this structural data in conjunction with the strength data of the carton to calculate the strength of a complete package design. "With powerful computers and qualified personnel at our disposal, we can run this type of simulation in a single day to help speed up the process of marketing a critical medicine," says Leskelä.