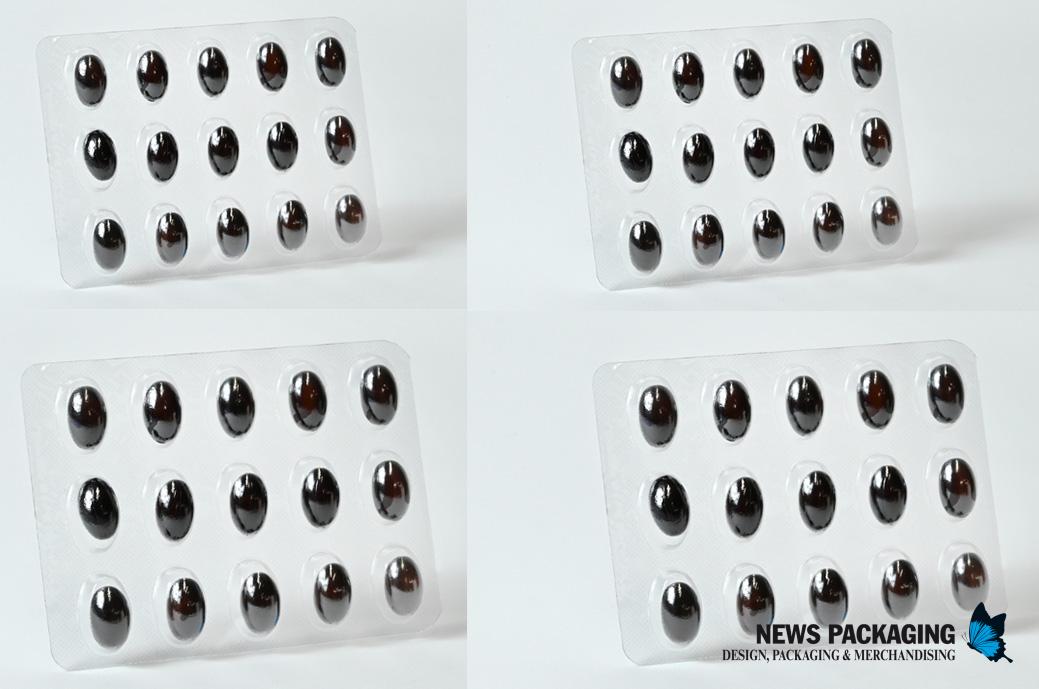

TekniPlex Healthcare has been associated with Alpek Polyester to present the first pharmaceutical grade blister film with post-consumer recycled content 30% with Alpek's Octal rDPET™. In sheet technology, blister film is also fully recyclable.

Suitable for a wide range of primary packaging applications, Alpek Polyester's Octal rDPET™ film technology incorporates a 30% PCR content based on mass balance. When combined with TekniPlex polyester cap, Teknilid® Push, the film plus cap blister system, is also fully recyclable in the polyester recycling stream where recycling infrastructure exists.

Directly integrated depolymerization, an aspect of Alpek Polyester's Direct-to-Sheet process, allows post-consumer and post-industrial plastic waste to be decompressed back to its monomer state, then reconstructed as a new polymer and transformed directly into sheets without compromising the attributes of performance. Octal rDPET™ Pharma Grade products provide the ability to return post-consumer and post-industrial waste to new PET sheets repeatedly without degrading the mechanical or optical properties of the film.

The new benchmarking blister film meets all pharmaceutical requirements for PET as described in Section 3.1.15 of the European Pharmacopeia and Section 661.1 of the United States Pharmacopeia.

Among other benefits, the adoption of the new Octal rDPET™ blister film with PCR content allows pharmaceutical companies to get ahead of pending sustainability legislation that will affect packaging across industries, without losing quality.