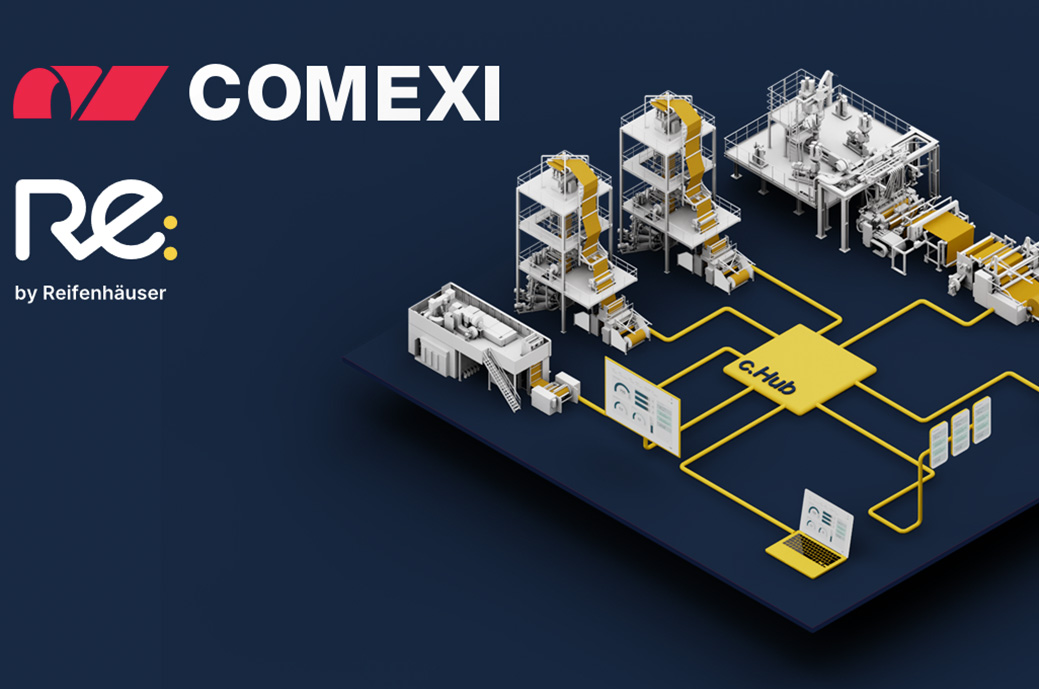

RE: GmbH and Comexi announce their innovative collaboration with the aim of advancing the digitalization within the sector of flexible plastic extrusion and packaging, with the purpose of establishing new standards in the industry. In a joint effort, the companies are taking a comprehensive approach that allows plastic processors and flexible packaging converters to seamlessly connect their entire production facility.

Plastic processors and flexible packaging producers around the world are struggling to integrate data from their conversion processes into the overall production picture. This covers a wide range of critical processes, from print and sealing quality to coating, lamination and waste management. Existing siled applications have hindered comprehensive process integration and therefore eliminated valuable optimization opportunities.

To address this challenge, RE: GmbH, a corporate start-up of the Reifenhäuser Group specialized in digital solutions for industry, and Comexi, a provider of printing, laminating and cutting solutions, have pooled their expertise.

“At Comexi, we strive to be at the forefront of innovative advances in the flexible packaging sector. Partnering with RE: GmbH is a coherent step for us to continue delivering value to our customers. Our cooperation goes beyond the mere integration of conversion processes. “We are inaugurating a new era of productivity, quality and sustainability throughout the production chain,” he says. Jordi Sahun, director of Innovation and Technology at Comexi.

Daniel Kajan, Director of Products and Operations at RE:, adds: “By integrating their conversion operations with c.Hub Middleware, our clients will achieve unparalleled operational effectiveness, more precise decision making and a strong competitive advantage in a market of fast pace.”

.